POWER MOVE

Creative thinking gets Boh out of logistical tight spots during Entergy marine repairs

When R.R. Cassidy Inc. asked Boh Bros. to assist with the emergency marine repairs of six water-based transmission poles after Hurricane Ida, it became obvious that the site’s tight conditions and numerous underwater obstructions would require an atypical approach.

The hurricane had damaged a significant number of poles that fed power to the Chauvin community, and even though the Cassidy team could perform repairs in the marsh, they needed Boh to do the marine repairs over water. More importantly, the repairs needed to be done in a hurry. “We began talking with them on Sept. 8 and by Sept. 11 we were receiving materials and prepping the barges,” says Kyle Alexander, Boh’s project manager.

Pile foremen Corey Price and Sean Barbarin initially surveyed the site by airboat and found an area literally surrounded by devastation. “Roadways were hard to navigate due to powerlines being down, debris, etc., but we were able to get down there by weaving our way through,” Price says. “We took some water depth readings and checked access routes. All of that was done ahead of time. We were fairly confident that we could get to those locations with our shallow water equipment and tugs, and we got the ball rolling.”

In the beginning, Entergy had difficulty finding materials, so they shipped whatever they could find to Boh’s Almonaster yard. “They used our yard as a central shipping location for power poles, casings, and any other materials that were needed,” Alexander says. “We had trucks coming from all over to bring this material to our yard. They were literally scavenging the entire country to find material.”

Transporting everything from Almonaster to the jobsite was no easy task, either. The hurricane had caused significant damage to the Intercoastal Waterway—there was sloughing in the channel some 20 miles west of Lafitte—so it was closed to large barges. That forced Boh to find an alternate route. “Instead, we had to go up the Mississippi River and back down through the Port Allen Locks, then through Dulac and Cocodrie to get to Chauvin,” Alexander says. The entire trip took about two and a half days.

Working in a Maze

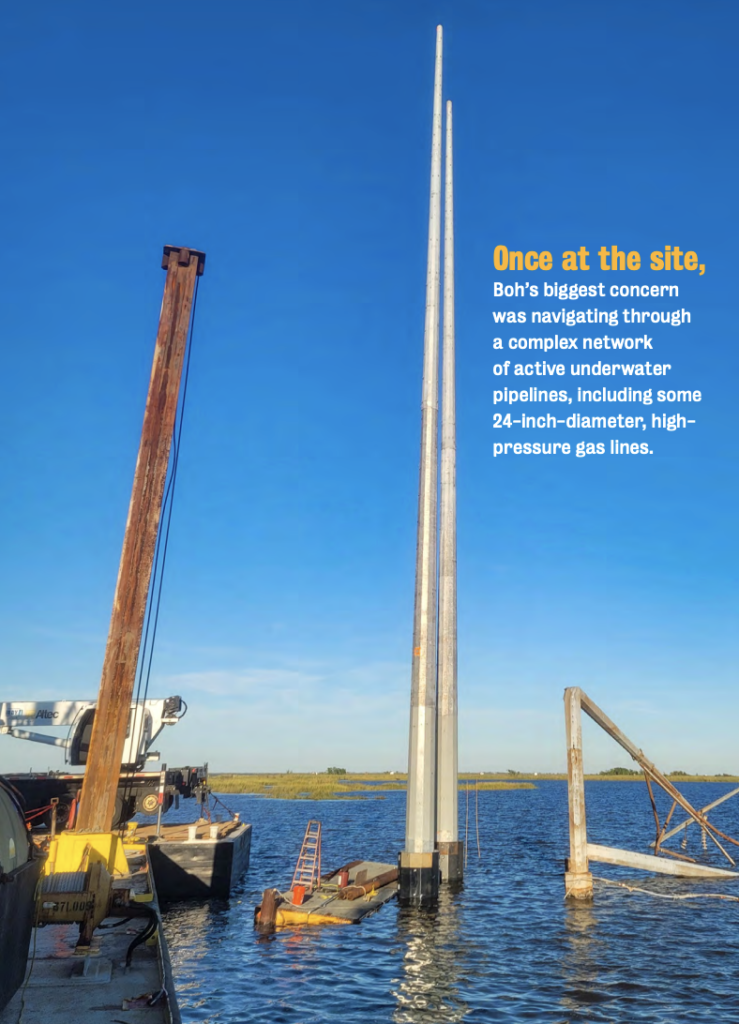

Once at the site, Boh’s biggest concern was navigating through a complex network of active underwater pipelines, including some 24-inch-diameter, high-pressure gas lines. Any damage inflicted by a barge, spud, or pile could have been catastrophic. “The lines run through an old oil field, so there were pipelines and flowlines scattered like spaghetti all over the place,” Alexander says. “We’re familiar with working on the water…we do that a lot. But the maze of utilities and pipelines was significant.”

Quanta (R.R. Cassidy’s parent company), the pipeline owners, and survey teams worked collaboratively to locate and mark the lines with cane poles, as well as document their depths, then divers re-verified that barge, spud, and pile locations were clear once the Boh team arrived on site. Water depths would typically average between 5 to 7 feet deep, but at times would be as shallow as 3 feet due to tidal flow and wind.

Price credits the divers for being critical to the marine repair project’s success. “We stayed in constant contact with them, either in person or by radio,” he adds. “And when we encountered an obstruction, we would move the tower toward or away from the canal to miss a line.”

Most of the power poles at the Chauvin site had fallen over or were too damaged to repair, so Boh had to drive new, 48-inch-diameter, 50-foot-long caissons adjacent to the existing locations, then install the new poles using a vibratory hammer. Next, an Irby crew would hang the lines and conductors.

It was an extremely tight site, so the project team had to creatively maneuver a 165-ton lattice boom crane, pile driving equipment, templates, caissons, and poles around existing transmission lines that were still in the air—all while working from a barge with limited space. As one logistical solution, Price and Barbarin sketched out a unique “floating template,” then asked Trey St. John, Boh quality control manager, and the Almonaster team to fabricate the system in short order. Incredibly, the work was completed in less than two days.

The two-piece floating template—built similarly to a pontoon with capped pipes that provide buoyancy—was positioned on location, bolted together, then spudded down with a crane. “After the pile was driven, we’d pull the spuds, unbolt it, pull it apart, and float it to the next location,” Price says. “Without it, we would have had to drive temporary piles and build a template on top of them or weld a template on top of the barge.”

The Boh team was able to physically float the template into place. “We’d spud it down and it was ready to go,” he adds. “It was faster and easier to maneuver. There were single pile setups and double-pile setups, so we designed it to support both.” With the template in place, the team would then drive one or two caissons to grade, as needed, remove the template, then set and drive 105-foot-long galvanized steel poles. Some of the configurations were H-frames, so two poles were driven with a cross brace for support.

Throughout the project, safety was paramount. Boh would conduct safety meetings prior to each day’s work to discuss challenges and concerns, then mitigate any potential safety hazards. “We went through those procedures several times,” Alexander adds.

Fatigue was another potential safety threat. The team worked seven days a week throughout the one-month project, often leaving their homes at 3 a.m. and not returning until late that night. To mitigate the potential of fatigue on safety, Quanta offered food and housing in nearby Houma for all workers.

In the end, the project was an unparalleled success. The Boh team completed the marine repairs in only a month, and without an established deadline. “It was a fast-paced environment, as it always is following a hurricane,” Alexander says. “They would tell us what we needed to do, then we would do it. Everyone understood the urgency.”

Recent Comments