Lifting Lafitte

Sensitive removal of damaged Lafitte swing span requires a creative solution

The Kerner Bridge over Bayou Barataria took a direct hit from Mother Nature on August 29, 2021. Hurricane Ida sent a barge careening into the bridge’s aging 200-footlong swing span, knocking it off its turntable foundation and causing irreparable damage.

Boh Bros. had performed similar repairs on the same span just a year earlier, but Ida was the last straw. Contractor CEC Inc. of Lafayette reached out to Boh for help in removing the structure from its footprint and replacing it with a temporary span to allow time for DOTD to develop a permanent fix.

The project demanded a quick turnaround. While the National Guard had installed a temporary floating bridge a few miles south of Lafitte, it could only support one vehicle at a time, and wait times were up to two hours long. As with most hurricane repairs, the deadline was ASAP. “They wanted us to complete the job as quickly and safely as possible,” says Grant Closson, Boh’s project manager at the site. “We worked swiftly to get the bridge back open.”

It was obvious that lifting the damaged span with a crane was too risky, given its age and instability. Besides, most of the cranes in the area were already being used on other repair projects. The Boh team began looking for low-risk ways to lift and remove the bridge. “The span was in a precarious state, so we had to come up with ideas for picking it up while minimizing the danger of it sliding into the water,” says G. J. Schexnayder, Group Manager— Heavy Construction. They ultimately devised a rather unconventional plan that involved sliding two barges, each ballasted with water, beneath either side of the span, then pumping out the water to raise the span with the barges.

Having worked on the Lafitte bridge in the past, Boh already knew the weight of the swing span and was familiar with the bridge’s design. As such, Boh’s chief engineer, Neil Hickok, was able to quickly develop a demolition plan, calculate buoyance capacities and determine the appropriate positioning of the barges. “It was a lot safer than using a crane,” Schexnayder adds. “If anything had gone wrong, it would’ve only damaged a barge, not toppled over a crane.”

Fortunately, Boh had preemptively secured equipment and materials prior to the storm making landfall and so had little difficulty finding the tugboats and barges it needed. When the Boh team arrived at the site, CEC was already in the process of removing the bridge’s timber driving surface in order to lighten the span’s weight.

The team transported a barge-mounted crane to the site and “spudded it down” in front of the swing bridge turntable, while two rented material barges were used for the actual lifting. The Boh team worked from the water, while the CEC team assisted from the shore or bridge. The crane assisted with grabbing pumps and other support equipment from the bank. It was a delicate operation, Closson says. While barges had been used for lifts before, “it’s not something we see every day.”

The Boh team first pumped water into the barges using 8, 6-inch pumps, four on each barge. “The entire time we were monitoring water levels and observing how the barges were reacting,” he adds. “You can’t just pump the water into one end, or you could actually break the back of the barge, or the barge could become unstable. You definitely need to pay attention and know what you’re doing.”

Once the barges were positioned and secured beneath the bridge, the team gradually raised the bridge span by “de-ballasting” the barges. The Boh team moved the barges and span away from the bridge, then inserted a third barge beneath the middle of the span for additional support. “We used the same approach with the third barge—pumping water into it so it could slide underneath, then pumping the water out,” Closson says.

The crew then dismantled the bridge section, with CEC cutting the bridge into four sections and Boh lifting and setting the sections on the bank.

A Temporary Fix

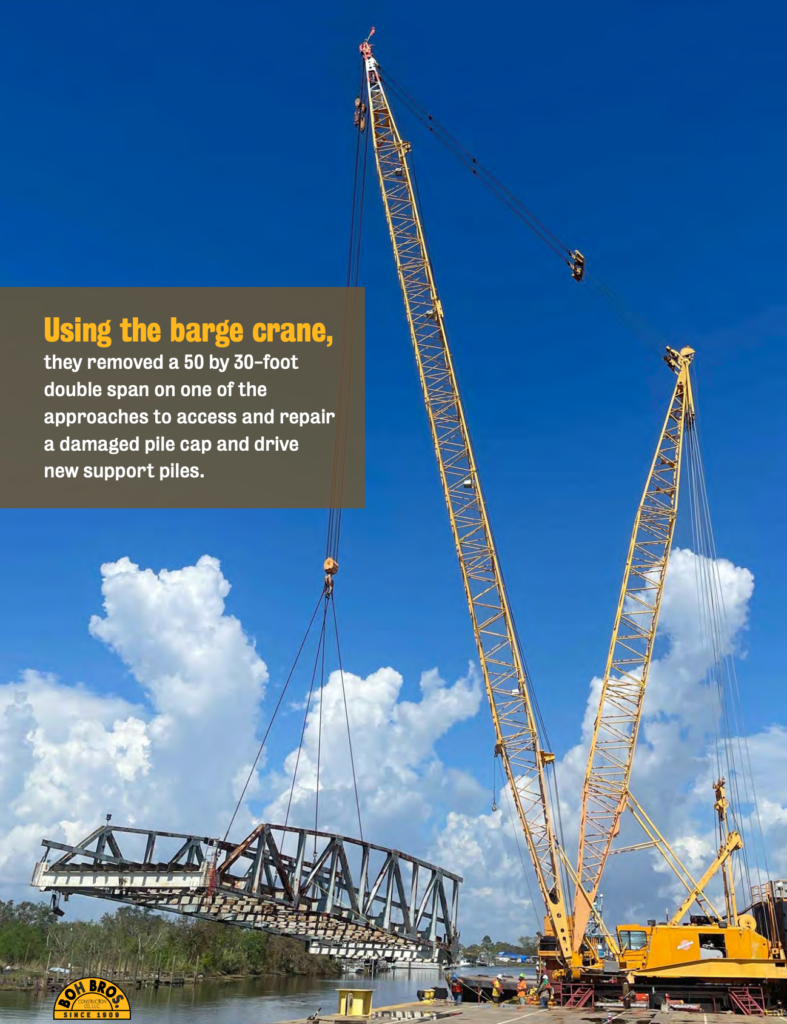

Turning its attention back to the bridge, the Boh team began repairing damage to the approaches to make way for the temporary span replacement. Using the barge crane, they removed a 50 by 30-foot double-span on one of the approaches to access and repair a damaged pile cap and drive new support piles.

CEC provided the engineering and Boh performed the lift. “We came back with six new 95-foot-long steel piles (already in Boh’s inventory) and a temporary cap, then reset the span,” Closson says.

The team then installed steel beams as support for the bridge turntable, then set the temporary steel bridge in two sections measuring 100 by 30 feet each. “CEC assembled the sections on a barge next to the site, pushed it over to us on the barge, and we picked it up with our crane and set it,” Closson says. The driving surface is made of precast panels and a layer of asphalt, all of which were delivered to the site, then lifted and placed from the materials barge. Once the bridge sections were in their final position, CEC anchored everything into place.

There were challenges encountered along the way, most of them to be expected when working in an area impacted by a hurricane. “Needless to say, they didn’t have any power in the area,” Closson says. “There were no gas stations, water, etc., and if we needed a tool we couldn’t just run to the local hardware store.”

The Boh team worked sunup to sundown, seven days a week throughout the three-week project. Safety was a concern throughout. “We made sure that everyone stayed focused, and if it was too much for someone due to their own Hurricane Ida recovery at home, we let them go home and take care of what they needed,” he adds. “As always, the focus of our projects starts and ends with everyone going home safe.”

Recent Comments