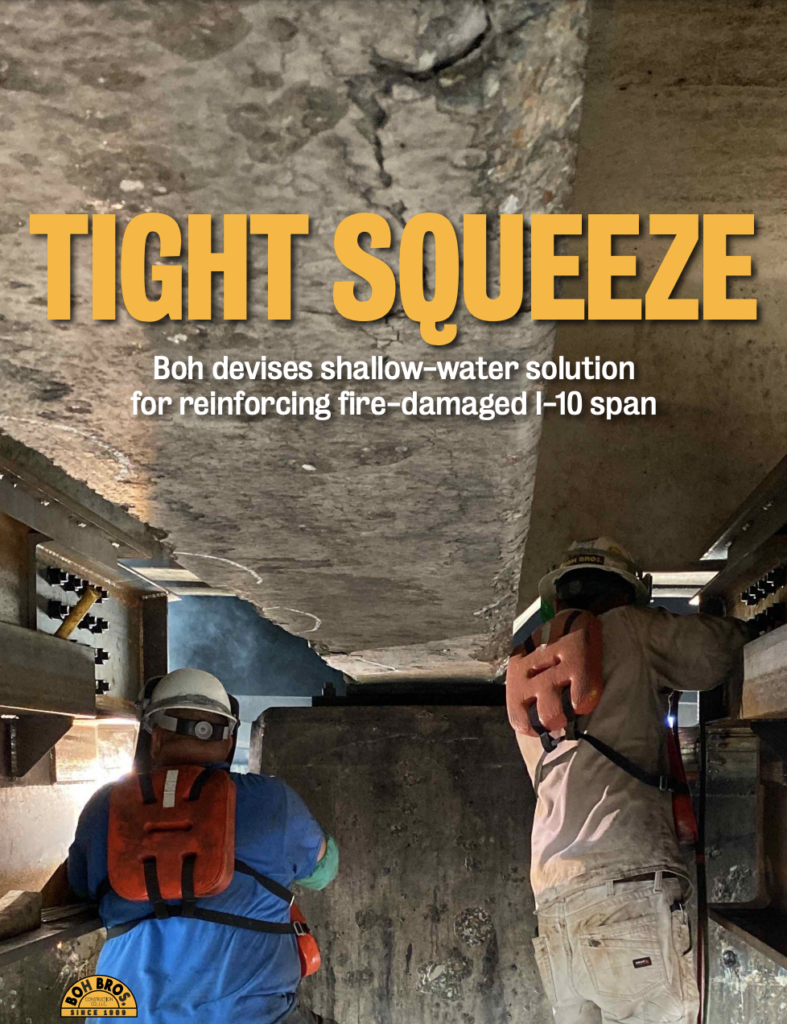

The intense heat generated by a September tractor-trailer rig accident and fire on I-10 eastbound into New Orleans had spalled and cracked the elevated span’s concrete superstructure, and LADOTD needed a quick fix. While the span’s girders still provided sufficient support, a structural analysis determined that additional support was needed until a full assessment could be performed.

Engineer Huval & Associates of Lafayette and LADOTD universally agreed that the fastest and least invasive approach would be to add steel “assist girders” to the underside of the span to reduce loads on the existing fire-damaged concrete girders temporarily.

Most importantly, LADOTD wanted the work to be completed quickly and with minimal disruption to traffic. The heavily used stretch of interstate is near the I-310 interchange, and while truck traffic had been temporarily banned from the area, normal vehicular traffic continued.

LADOTD asked Boh Bros. to perform the work under an emergency time and materials contract. “Huval came up with the assist girder concept, and we offered constructability input,” says G. J. Schexnayder, Group Manager—Heavy Construction at Boh. “Their primary objective was to reduce the loads on the existing fire-damaged concrete girders, and in doing so improve the stability and safety of the structure.”

During an initial boat ride to the site, Boh Heavy Construction Field Operations Manager Bill Moulton and General Superintendent Vincent Rabalais immediately realized that accessing the area with conventional marine equipment would be impossible. Water depths under the span were as shallow as 2 feet, and tugboats required at least 8 feet of draft. “To get the materials out there, we would need an unusually shallow-draft barge,” Rabalais says.

Fortunately, Boh already had what it needed—a 30- by 60-foot shallow-draft barge sitting at its Almonaster yard. “The next day, we were identifying the equipment that we would need, as well as planning the process and fabrication sequence to ensure that we had everything we needed,” Rabalais adds.

Time was of the essence, as everything had to be fast-tracked to meet LADOTD’s timeline. The Boh team began fleshing out the details and weighing their options for transporting the beams and other materials from Almonaster to the bridge site without tugboats. Precision at the site was equally critical since the girders had to be installed from beneath the bridge with only 8 feet of wiggle room—and in extremely shallow water.

A Creative Solution

A Creative Solution

An expedited fabrication effort at Boh’s Almonaster yard kicked everything off. By the following weekend, a 20-person team was already procuring materials and fabricating beams while also dealing with significant supply chain issues. “The girders we located weren’t the correct length,” Schexnayder says. “Ideally, we would’ve liked 60-foot pieces of steel ready and available. That wasn’t the case, so we had to splice them together. It was also difficult finding all of the bolts that we needed, but our procurement guys managed to track everything down.”

The Almonaster team ultimately fabricated 16 beams measuring 150 pounds per foot, and 36 inches tall, all bolted together in eight pairs. Other job materials included heavy channels for support pieces, splice plates, bolts, and other miscellaneous steel. “The goal was to get all of the beams and other materials completed accurately and on time to get them to the site for installation,” Schexnayder adds. “It could have become a time-consuming process, but we finished in record time. Like on any other job, we had to get every shop drawing approved by the engineer.”

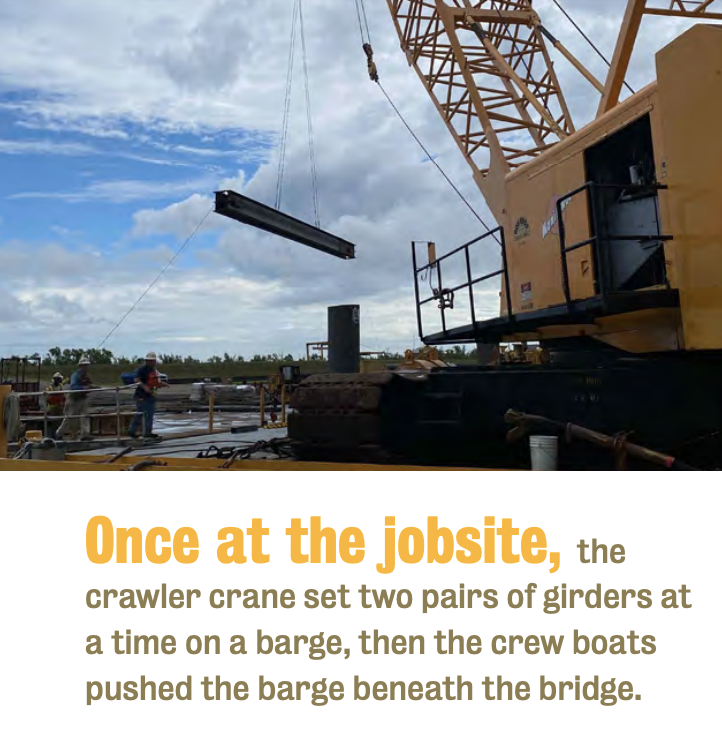

Getting it all to the site became a multi-step journey—the Boh team used tugs for the part of the trip, pushing a Manitowoc 4100 barge-mounted crawler crane and material barges as close to I-10 as possible via the Duncan Canal (aka West Return Canal) along the Kenner floodwall. They then offloaded the beams and other materials onto the shallow-draft barge, which was then pushed the rest of the way by aluminum crew boats with 24-inch drafts.

Once at the job site, the crawler crane set two pairs of girders at a time on a barge, then the crew boats pushed the barge beneath the bridge. “No doubt, we were operating at the edge of where we could work,” Schexnayder says. “The water elevation fluctuated a bit due to the wind, and at one time, the barge was even sitting on the bottom. Still, for the most part, we were able to get it done without any major hiccups.”

Once at the job site, the crawler crane set two pairs of girders at a time on a barge, then the crew boats pushed the barge beneath the bridge. “No doubt, we were operating at the edge of where we could work,” Schexnayder says. “The water elevation fluctuated a bit due to the wind, and at one time, the barge was even sitting on the bottom. Still, for the most part, we were able to get it done without any major hiccups.”

Moulton and Rabalais had determined that the best approach for raising the beams would be to jack them up from below since using a large crane was out of the question. Therefore, the team first floated the girder pairs into place beneath the bridge, then rotated each beam pair into position on a barge-mounted turntable and raised them into place using 4 ea. 25 Ton hydraulic jacks. Cribbing was installed between beams and the barge’s deck as the beams were raised. The beams were raised an average of 4’ above the barge’s deck.

The Boh team installed extended bearing channels after the beams were raised, which bore on the existing caps to support the beams. The Channels weighed 150lbs each and would have been difficult to install due to the limitations of the workspace between the existing concrete girders and the new beams. The Boh teams designed and fabricated channel supports at the ends of the beams, which allowed the crew members to slide the channels into position before they began the bolting procedure. Boh also worked with Huval and Associates to develop a jacking plan to preload the beams for final shimming and blocking. The Boh Team fabricated jacking brackets that bolted to the existing concrete caps using 1” diameter x 9” wedge bolts. Before jacking, wood blocking was placed between the bridge deck or the existing diaphragms and the assist girders. The crew preloaded the assist girders using 4 each 25 Ton hydraulic jacks. 12”x12” steel bearing plates were installed between the caps and the channel support brackets.

A 12-person Boh crew performed the work under the supervision of superintendents Wesley Drumright and Wayne Bremermann. Of course, safety was a concern throughout the process, given the access issues, tight work environment, and other constraints. “There was very little headroom and very tight logistics,” Rabalais says. “We began with about 8 feet of room, then had to shove a barge with giant steel girders underneath there. That took it to a whole different level. That’s a lot of big pieces that you have to move around.

A 12-person Boh crew performed the work under the supervision of superintendents Wesley Drumright and Wayne Bremermann. Of course, safety was a concern throughout the process, given the access issues, tight work environment, and other constraints. “There was very little headroom and very tight logistics,” Rabalais says. “We began with about 8 feet of room, then had to shove a barge with giant steel girders underneath there. That took it to a whole different level. That’s a lot of big pieces that you have to move around.

“We had to have a very well thought out work plan to ensure that everything was executed safely.”

A Creative Solution

A Creative Solution

Recent Comments